Maxim Gökova

Sabanci University

Undergraduate

Materials Science and Nano Engineering (Bachelor)

Electronics Engineering (Bachelor)

Chemistry (Minor)

Timeline of Academic Studies

Nov 2024 - Current

SU-IMC Istanbul, Turkey

SU Integrated Manufacturing Technologies Research and Application Center

Principal Researcher

High Thermal Conductivity PMCs based on Diamond Nanoparticles

Polymer Matrix Composites (PMCs) are one of the mostly used materials in aerospace and automotive applications due to their high mechanical strength and low weights. However, extremely low thermal conductivity of polymers leads to thermal bottlenecks in high temperature aerospace and automotive applications where dissipation of the heat is critical. The solutions proposed up to date concentrated on the usage of high thermal conductivity fillers such as graphene and CNTs. However, recurring studies demonstrated the inefficiency of 2D fillers in providing sufficient heat dissipation in the matrix, resulting in thermal failure. Thus, today, heat dissipation still stands out as one of the most important problem areas in aerospace and automotive applications.

Our study proposes a new filler type, diamond nanoparticles, to be used in PMCs in order to reach thermal conductivity levels that was unattainable by CNTs, graphene, or h-BNs up to date. In order to lay the theoretical foundation of the study, a detailed analysis of heat conduction mechanisms in polymers and crystals at phonon level has been made, and phonon scattering mechanisms of diamonds has been compared with 2 dimensional fillers to explain how diamond nanoparticles are better thermal conductors when used as fillers in a polymer matrix.

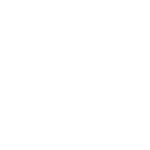

Automated Fiber Placement Machine | SU-IMC Facility

The project is being conducted in SU-IMC, the biggest Composites R&D center of Turkey. I am the main researcher and engineer of the project. The foundations of the project is rooted during my R&D studies at Appsilon Enterprise, a Turkish company that produces diamonds in lab environment. I am conducting this study under the supervisions of Prof. Burcu Saner Okan, and Prof. Bekir Dızman, who have vast experience in composites industry.

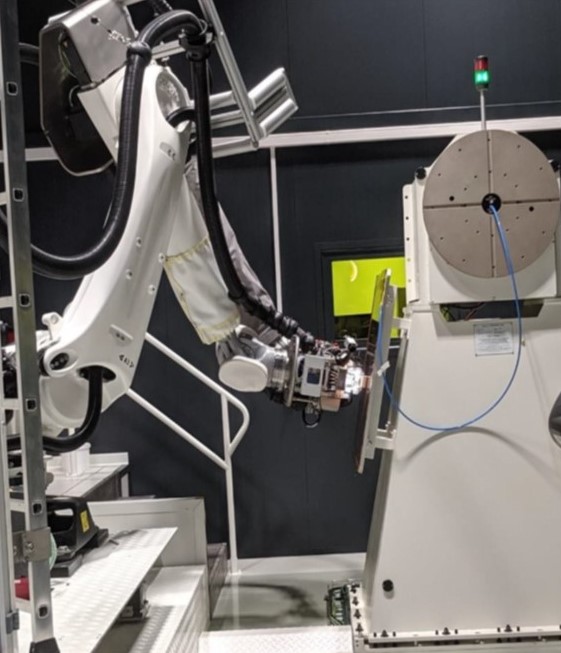

Advanced Composite Fabrication Laboratory | SU-IMC Facility

Co-principal Researcher

Engineering High-Performance Thermal Insulators Made from Sustainable PA and ABS Compounds with Lower CO2 Emissions

It is estimated that 12,000 tonnes of EPS (expandable polystyrene) is disposed of to landfill each year, taking up 240,000 cubic metres of landfill space. The purpose of this project is to develop thermal insulators from newly enhanced recycled PA and ABS compounds, and to replace the usage of EPS in white goods industries, contributing to Turkey’s sustainability goals.

By adding fillers, reinforcements, and additives to the recycled polyamides, it is possible to further improve and tailor their properties. Through this project, we aim to develop a high-value, sustainable thermally insulator compound made from mechanically recycled polyamide66 and ABS blends, enhanced with fillers, reinforcements, and additives. Within the project, CO2 emissions will be calculated by life cycle assessment program.

Wet Chemistry Laboratory and Material Characterization Laboratory

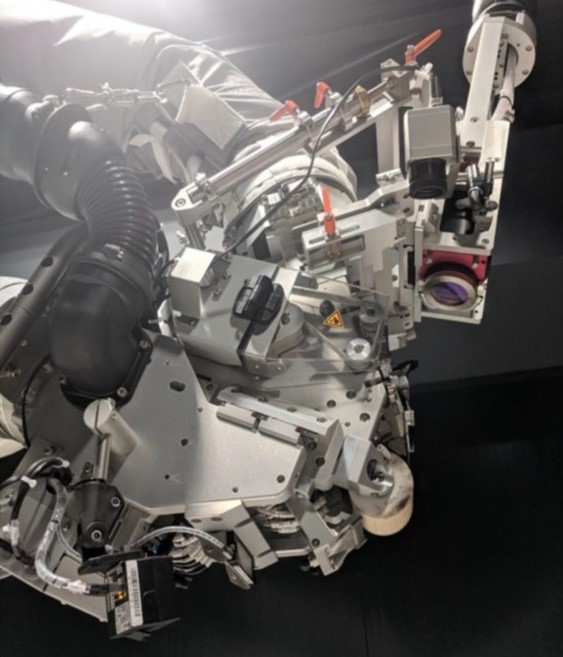

This is a joint project between KORDSA and Sabanci University. KORDSA is one of the biggest composite manufacturers in the world, accountable from producing two-thirds of the aircraft tires in the world.

Project Supervisor: Prof. Burcu Saner Okan

KORDSA in Global Market

Sep 2024 - Current

KORDSA & SU Istanbul, Turkey

Joint Project between Sabanci University and KORDSA Composite Technologies Center Of Excellence

July 2024 - Sep 2024

Appsilon Gebze, Turkey

Appsilon Enterprise | Lab Grown Diamonds

R&D Researcher

Lab Grown Diamonds | Process Optimization for High-level Thermal and Optical Applications

Appsilon is a company that produces lab-grown diamonds, using MPCVD method (Microwave Plasma Chemical Vapor Deposition). I conducted a summer internship at Appsilon where I studied on the optimization of both company’s diamond production processes and postprocessing (surface processing) methods. Additionally, I worked on the potential expansions of company’s product portfolio towards high-level thermal and optical applications. During the internship, I gave regular presentations to R&D team to report my findings and discuss further steps.

Diamond Growth Laboratory | Appsilon

Appsilon is founded in 2017 by 6 entrepreneurs to find a solution for thermal management problems experienced in high power electronics. Upon receiving a seed investment of 1.5 million Euros from Diffusion Capital Partners (DCP), the company set out to commercialize their research on lab-grown diamond production, and started mass production at the end of 2018. In 2022, company received another 12.5 million Euros of investment from Esas Private Equity.

Today, the company is conducting their operations in 2 different countries. Their Turkey office is located in Tübitak Martek, and their office at Delft, the Netherlands is specialized for developing quantum-based applications of diamond.

Individual Researcher & Inventor

Air Flow Regulation using MEMS Devices Based on Micro Air Controller Cell Arrays | Advanced Cooling Systems

Can we use MEMS devices to regulate air flow and get rid off all the bulk and heavy air controlling tools such as compressors, air pumps, or air conditioners?

This project aims to explore a concept that has not been subject to an attempt of discovery up to date. In this project, I designed and lay the theoretical framework of a new MEMS architecture for a new type of air flow control. The device is designed as a MEMS surface that comprises of thousands of electrostatically actuated microcells.

SUNUM Clean Room

After 4 months of extensive theoretical research, 80 pages of study report including calculations, schematics, and simulations, and 1 month of clean room experiments, the project is delayed due to the technical problems encountered during the electroplating of high-aspect ratio structures and lack of supply of certain compounds during the period of the project.

SUNUM Nanotechnology Research and Application Center

Feb 2024 - June 2024

SUNUM Istanbul, Turkey

Sabancı University Nanotechnology Research and Application Center

Aug 2023

University of Borås Borås, Sweden

The Swedish School of Textiles

University of Borås

Training School

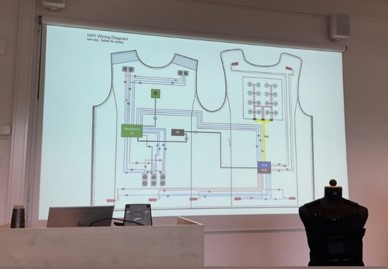

Wearable Electronics and Smart Textiles Training School | SOFTWEAR

A training school for soft wearable electronics and smart textiles. The relationship between progress in smart material technologies, science and textile/fashion design was the main topic of the training. Lectures included how to make smart textiles, the integration strategies, and the industrial aspects. One day was devoted to industrial aspects with a visit to the company Albany in Halmstad.

SOFTWEAR Community (Me standing as the 5th person from the left)

Marie Skłodowska-Curie Actions Doctoral Network SOFTWEAR is a highly interdisciplinary network consisting of 12 selected PhD students working uniquely on soft actuators for wearables.

Swedish School of Textiles

Summer Research Assistant

Artificial Muscles based on Silicon Dielectric Elastomer Fibers

I spent 3 months as a research assistant at the Danish Polymer Centre, Technical University of Denmark, Copenhagen, studying on artificial muscles and conducting the experiments. The project had received a grant of DKK 48 million from the Novo Nordisk Foundation prior to my arrival for the development of artificial muscles made from silicone and spider silk.

Publication:

Sina Jafarzadeh, Maxim Gökova, Zhaoqing Kang, Liyun Yu, and Anne Ladegaard Skov “Unveiling design criteria of hollow fibers dielectric elastomer actuators: a computational and experimental study”, Proc. SPIE 12945, Electroactive Polymer Actuators and Devices (EAPAD) XXVI, 129450O (9 May 2024); https://doi.org/10.1117/12.3010130

Tasks and Accomplishments:

– Conducted the synthesis of elastomeric fiber actuators (artificial muscles) using wet spinning and UV-photopolymerization methods and characterized the samples via micro-imaging techniques,

– Evaluated the tensile strength and the dielectric breakdown of the fibers by mechanical tests and controlled high-voltage actuation respectively,

– Evaluated the results of the experiments to establish a correlation between the experimental parameters and optimum fiber diameters,

– Mentored three newcomer researchers (2 PhD and 1 undergraduate) and taught them the experimental steps and techniques,

Me at the lab after a brief moment of victory 🙂

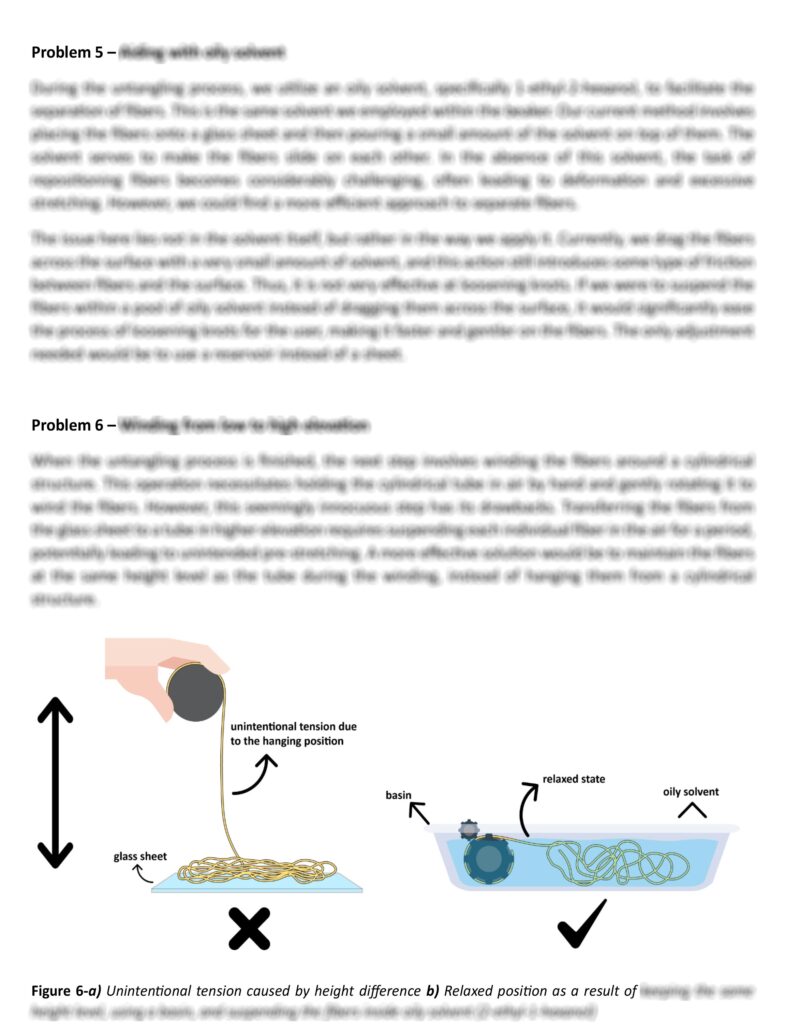

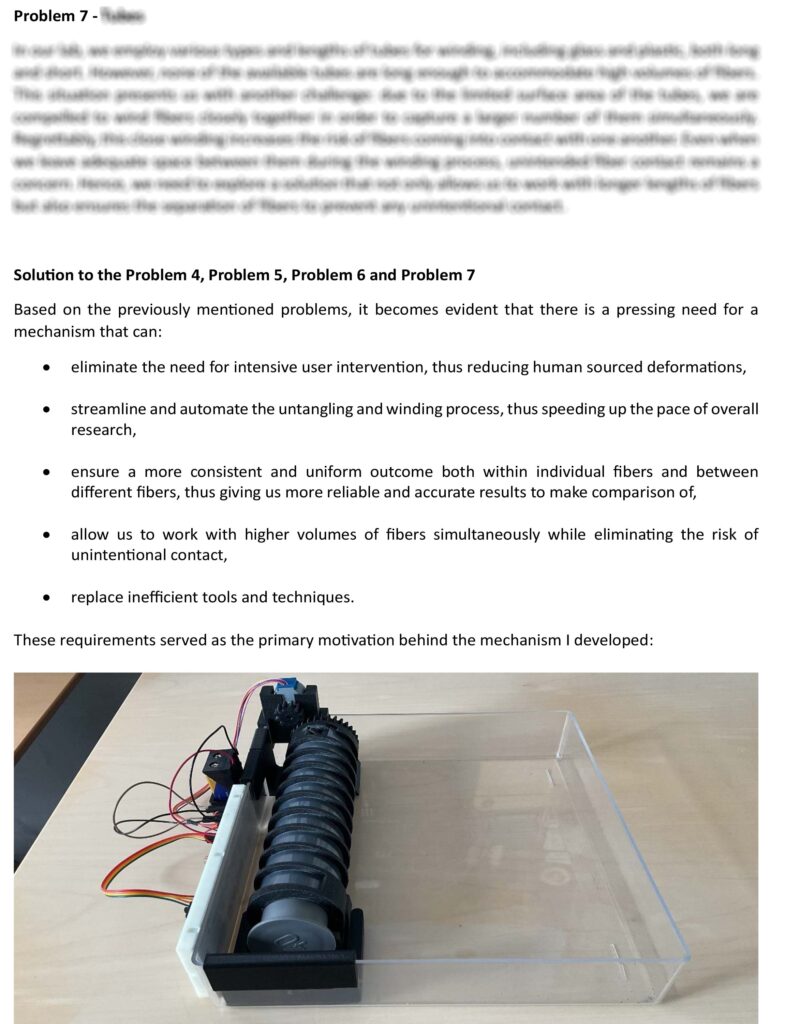

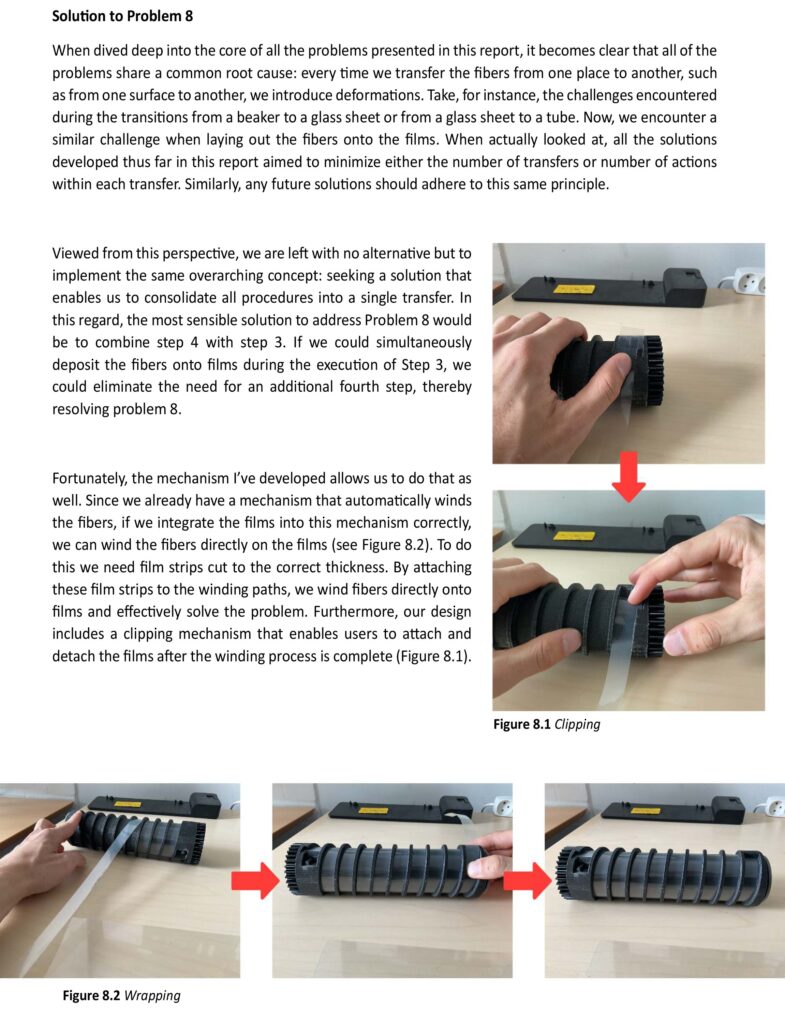

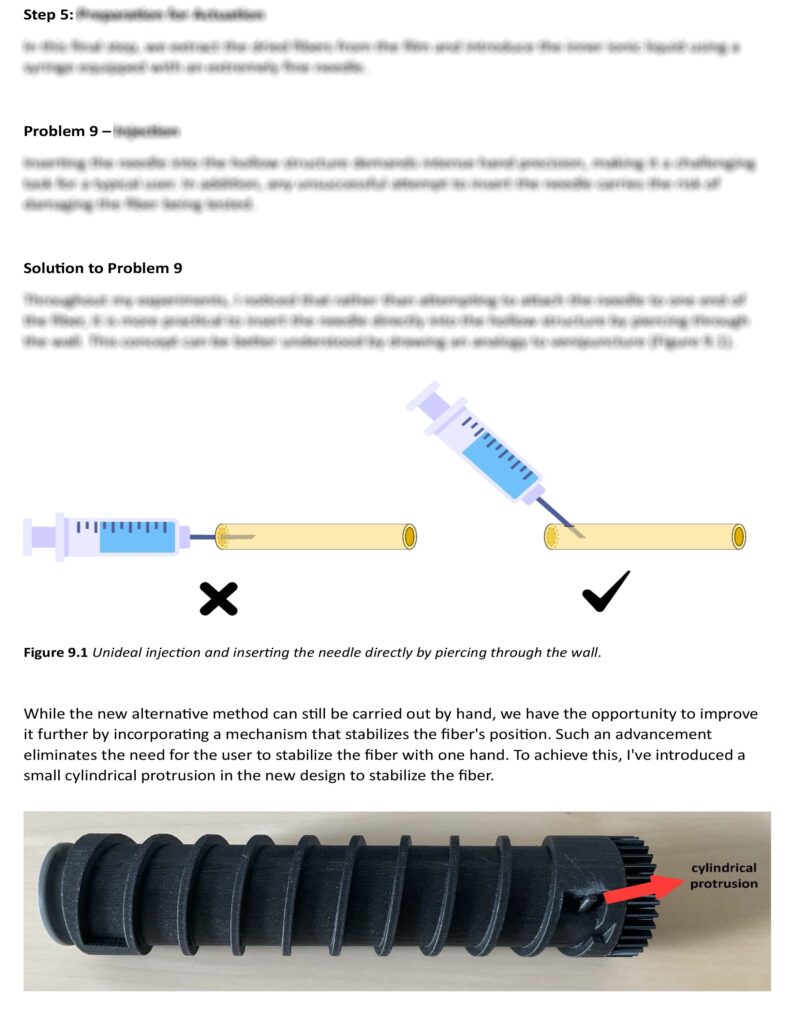

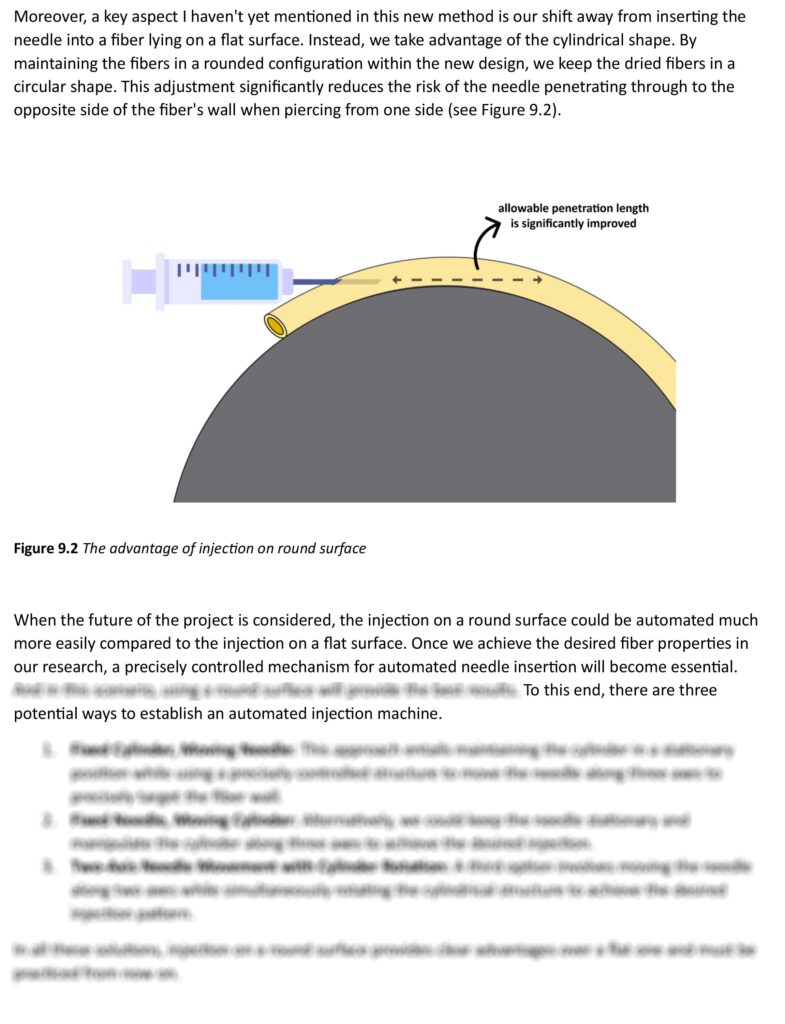

– Designed and manufactured an electromechanical system for the improvement of the fiber production and elimination of 9 major problems encountered during the production,

– Published a 15-page independent report explaining how to solve the current problems in the production steps, including those that have been already solved by the mechanism,

Selected parts of my report study and explanations of the mechanism

– Co-authored a paper detailing on optimal design criteria for silicon fiber actuators (artificial muscles) to be presented at SPIE EAPAD XXVI, March 2024, Los Angeles,

– Our study won top price in SPIE NDE 2024 “EAP-in-Action” Conference, Long Beach, California.

News

Our study winning top price in SPIE NDE 2024, Long Beach, California

June 2023 - Sep 2023

DPC-DTU Copenhagen, Denmark

Danish Polymer Centre

Department of Chemical and Biochemical Engineering - Technical University of Denmark

June 2022 - Sep 2022

SUNUM Istanbul, Turkey

Sabancı University Nanotechnology

Research and Application Center

Undergraduate Research Assistant

Stretchable Lithium-Ion Battery Component Production using Electrospinned Nanofiber Elastic Films

The ever-growing flexible and wearable electronics market and rapid technological developments have been the driving force in the development of energy storage systems that can stretch, bend, fold, wrinkle while maintaining their electrochemical performance. While many different strategies continue to be put forward to develop flexible and elastic energy storage systems, especially lithium-ion batteries and supercapacitors, the difficulties of developing new materials and configurations and designing simple and large-scale production methods that can be widely used cannot be ignored. In particular, the development of lithium-ion batteries and supercapacitors, which can be intrinsically stretchable is quite challenging, but there is a great need for those energy storage systems to power flexible electronic devices.

Tasks and Accomplishments:

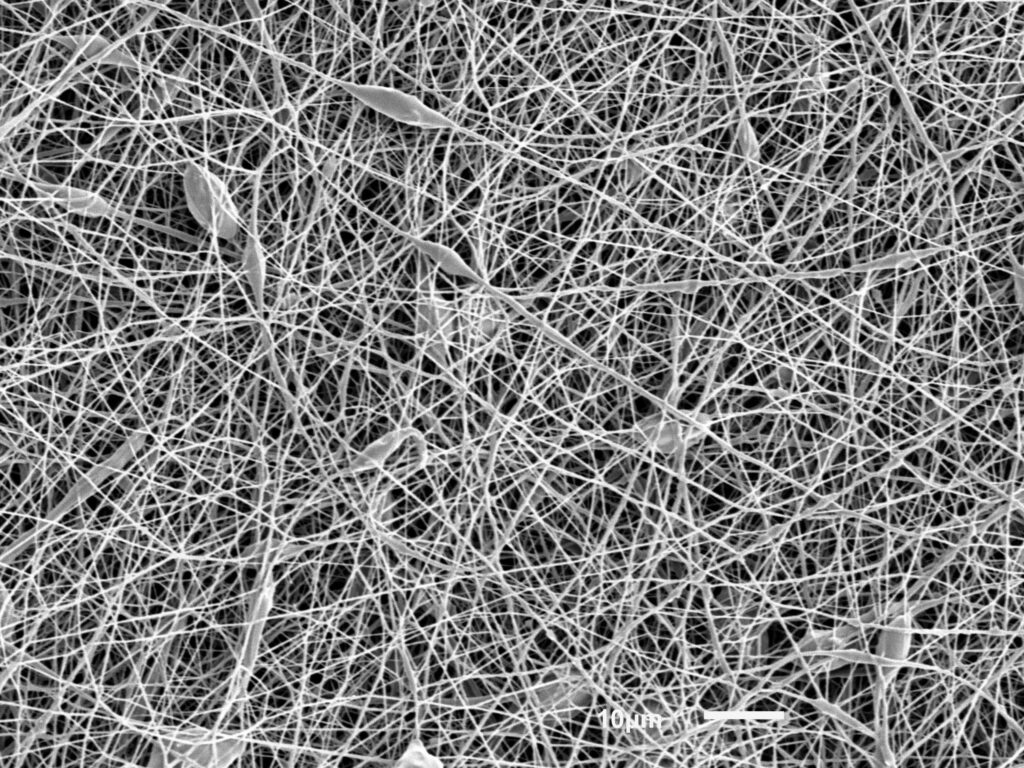

– Conducted a study on nanofiber based conductive elastic films that could be used as stretchable lithium-ion battery components,

– Analysed two different elastomeric polymers, TPU and SEBS, as candidates to be used in the synthesis of conductive and flexible nanofiber films,

– Published a report introducing the first steps of the production,

– Manufactured a polymeric surface that reaches 100% stretchability,

– SEM imaging and electrospinning methods are frequently used in the lab.

Electrospinning setup and SEM image of an electrospun nanofilm

Intern

Sustainability and Waste Management in Cement Industry

Akçansa is a construction materials company in Turkey that prioritizes sustainability. In this program, the operational activities inside the cement industry was experienced at first hand. The logistics, and manufacturing cycles of cement industry was analyzed by making site visits through the factories and ports. At the end of the internship, a small project about sustainability and waste management was conducted.

Facilities of Akçanca | Cement Factory & Ports

Jan 2022 - Feb 2022

AKÇANSA Istanbul, Turkey

Akçansa Çimento AS | Akçansa Cement Manufacturing Company

Oct 2021 - Jan 2022

SUNUM Istanbul, Turkey

Sabancı University Nanotechnology

Research and Application Center

Term Project

Thin-Film Coatings of Nanostructures via LbL Assembly

Prepared thin film coatings of nanostructures with polyelectrolytes to create functional surface properties. Our approach to creating thin-film coatings was layer by layer assembly technique that we control film properties at sub nano level.

Civic Involvement Project

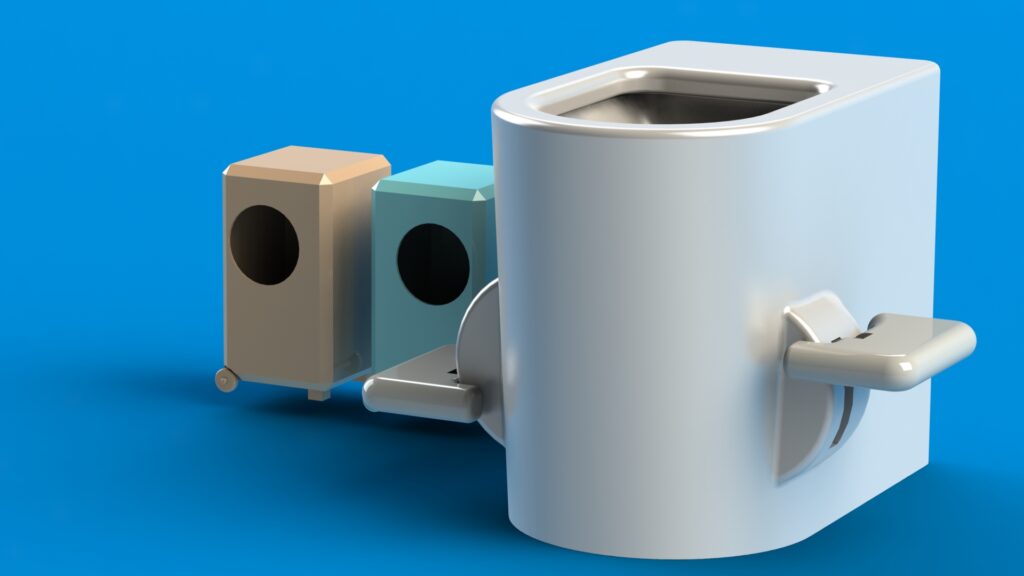

Design of a Water-free Siphon Mechanism to Prevent Sanitation Problems and Minimize Water Consumption

2.3 billion people are deprived of basic sanitation systems due to lack of plumbing. Excretory wastes released into rivers and soil cause the rapid spread of many tropical deadly diseases, causing 775,000 deaths each year.

Moreover, unsafe sanitation causes many social wounds in areas such as education and gender equality. After an extensive research, we offered an innovative solution to the topic and designed a water-free siphon mechanism via SolidWorks.

Feb 2021 - May 2021

SU Istanbul, Turkey

Sabanci University

July 2020

YKS Turkey

University Entrance Exams (YKS), Turkey, 2020

Exam Degree

974th place in Maths & Sciences | Full Scholarship

974th place in Maths & Sciences category of Turkey’s nation-wide University Entrance Exam out of 2.5 million entrants.

I earned Full Scholarship in Sabanci University and chose Materials Science and Nano Engineering department, becoming one of the 5 students in Turkey that receives Nano Engineering education at undergraduate level for my entrance year.