Maxim Gökova

Sabanci University

Undergraduate

Materials Science and Nano Engineering (Bachelor)

Electronics Engineering (Bachelor)

Chemistry (Minor)

Timeline of Extra Studies

Nov 2024 - Current

SU-IMC Istanbul, Turkey

SU Integrated Manufacturing Technologies Research and Application Center

Principal Researcher

High Thermal Conductivity PMCs based on Diamond Nanoparticles

Polymer Matrix Composites (PMCs) are one of the mostly used materials in aerospace and automotive applications due to their high mechanical strength and low weights. However, extremely low thermal conductivity of polymers leads to thermal bottlenecks in high temperature aerospace and automotive applications where dissipation of the heat is critical. The solutions proposed up to date concentrated on the usage of high thermal conductivity fillers such as graphene and CNTs. However, recurring studies demonstrated the inefficiency of 2D fillers in providing sufficient heat dissipation in the matrix, resulting in thermal failure. Thus, today, heat dissipation still stands out as one of the most important problem areas in aerospace and automotive applications.

My study proposes a new filler type, diamond nanoparticles, to be used in PMCs in order to reach thermal conductivity levels that was unattainable by CNTs, graphene, or h-BNs up to date. In order to lay the theoretical foundation of the study, a detailed analysis of heat conduction mechanisms in polymers and crystals at phonon level has been made, and phonon scattering mechanisms of diamonds has been compared with 2 dimensional fillers to explain how diamond nanoparticles are better thermal conductors when used as fillers in a polymer matrix.

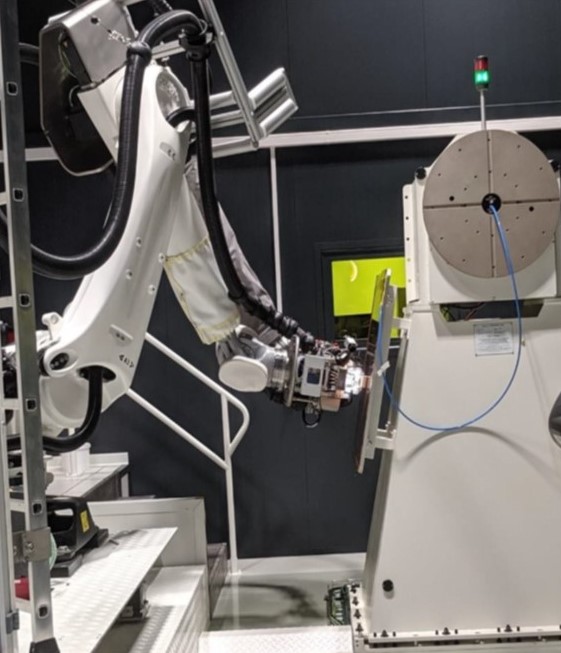

Automated Fiber Placement Machine | SU-IMC Facility

The project is being conducted in SU-IMC, the biggest Composites R&D center of Turkey. I am the main researcher and engineer of the project. The foundations of the project is rooted during my R&D studies at Appsilon Enterprise, a Turkish company that produces diamonds in lab environment. I am conducting this study under the supervisions of Prof. Burcu Saner Okan, and Prof. Bekir Dızman, who have enormous experience in composites industry.

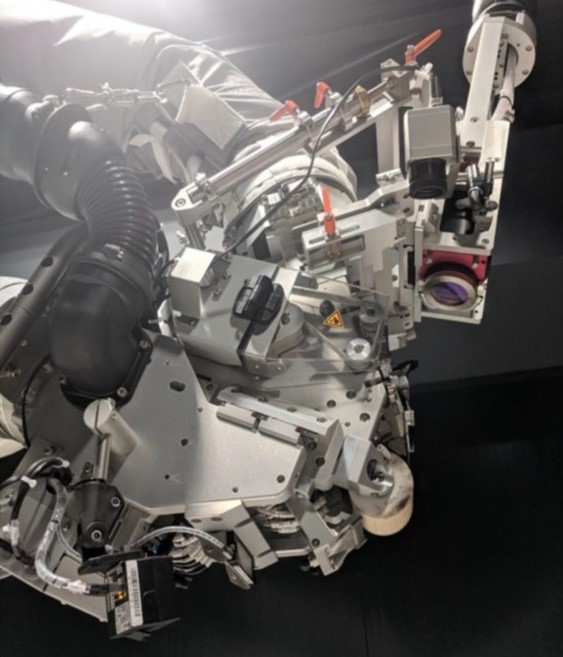

Advanced Composite Fabrication Laboratory | SU-IMC Facility

Co-principal Researcher

Engineering High-Performance Thermal Insulators Made from Sustainable PA and ABS Compounds with Lower CO2 Emissions

It is estimated that 12,000 tonnes of EPS (expandable polystyrene) is disposed of to landfill each year, taking up 240,000 cubic metres of landfill space. The purpose of this project is to develop thermal insulators from newly enhanced recycled PA and ABS compounds, and to replace the usage of EPS in white goods industries, contributing to Turkey’s sustainability goals.

By adding fillers, reinforcements, and additives to the recycled polyamides, it is possible to further improve and tailor their properties. Through this project, we aim to develop a high-value, sustainable thermally insulator compound made from mechanically recycled polyamide66 and ABS blends, enhanced with fillers, reinforcements, and additives. Within the project, CO2 emissions will be calculated by life cycle assessment program.

Wet Chemistry Laboratory and Material Characterization Laboratory

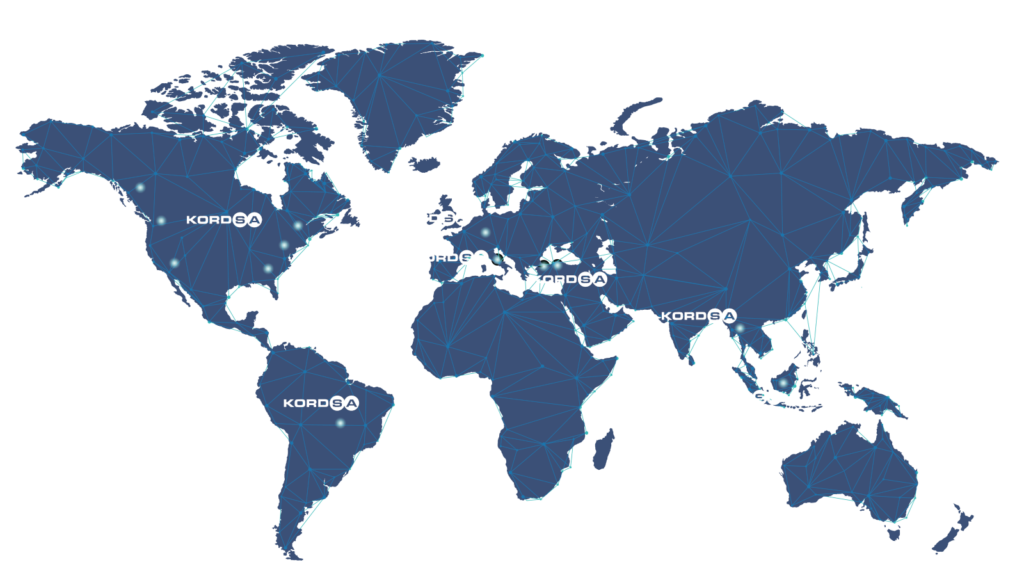

This is a joint project between KORDSA and Sabanci University. KORDSA is one of the biggest composite manufacturers in the world, accountable from producing two-thirds of the aircraft tires in the world.

Project Supervisor: Prof. Burcu Saner Okan

KORDSA in Global Market